Fabrication and Welding

The fabrication/welding shop is the beginning of the chassis and many small parts. The first part is frame rail fabrication. Each piece of rectangular 2" x 4" tubing is cut and put in a jig for MIG welding. This a special electric wire fed welding technique that ensures a tight proper bond between all the frame pieces. There are no voids, and no bubbles. The heat is controlled to make a perfect weld at each joint. We use a special welding jig for our frames so that all frames are the exact replica of the last one, or the next. As a result, Unique has the strongest frame in the industry. Our door hinges are fabricated from 1/4" steel plate, welded to two, 1" x 2" steel beams that run the entire length of our doors. This makes for a very strong door assembly that will not sag over time. Unique also fabricates their own roll bars, headers, sidepipes and cowl braces. By building these items in-house, we control both the quality, and the production supply time. All the roll bar brackets, body mounting points, engine and transmission mounts are fabricated and installed by the Unique factory. There is absolutely no welding required by the customer on a Unique kit.

The first picture shows the beginning selection of raw steel materials for a set of frame rails. In the second, you see the first welding on the frame as it begins to take shape.

Next, we see the frame in the special welding jig as it begins to look like a frame. After the frame is welded up, the headers and pipes are fabricated using "dummy engine blocks" to get it just right. An example of a completed welded set of headers is shown below.

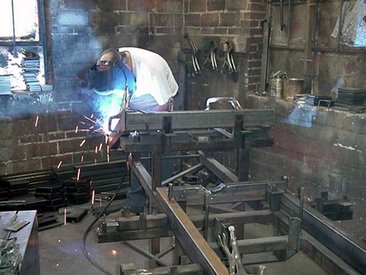

This shot shows Maurice Weaver putting the finishing touches on a set of custom sidepipes after they have been fitted to a frame and engine combo. The headers were formed actually bolted to an engine block of the customers choice. This is a standard deluxe kit item, not an extra option at Unique. Glass pack mufflers are used as standard too, no home made 1" tube side-by-side internal pipes here! Many kits use these cheap pipes which cut down your power by a substantial margin, not Unique, only the finest components here!

Now we see the final frame structure in completed form. This frame just came back from powder coating, and is now ready to accept the suspension components in the Assembly Shop .

This is the end of the fabrication Shop tour, next, is the Assembly Shop (please click here to continue with the factory tour).